Conveying by timing belt

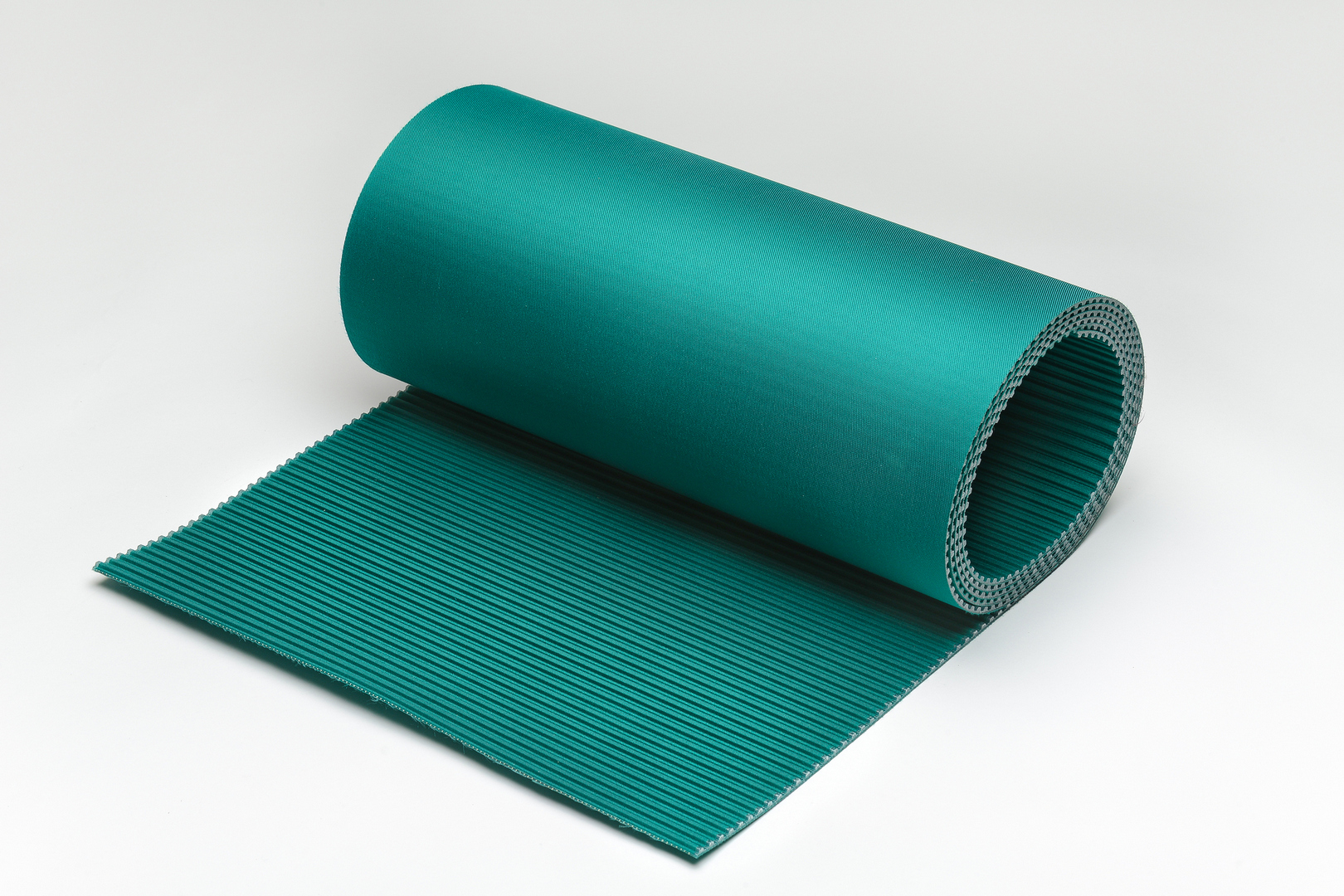

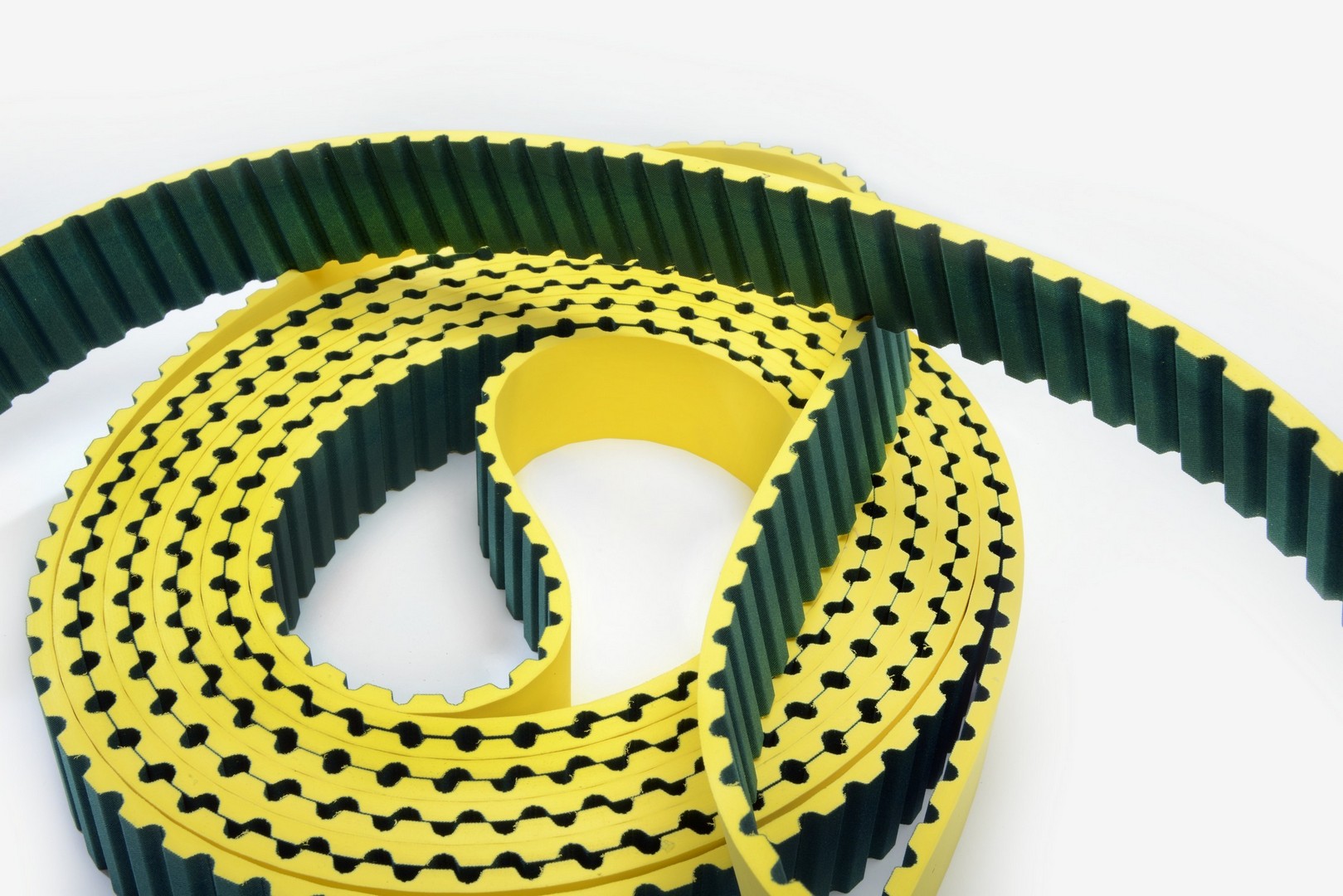

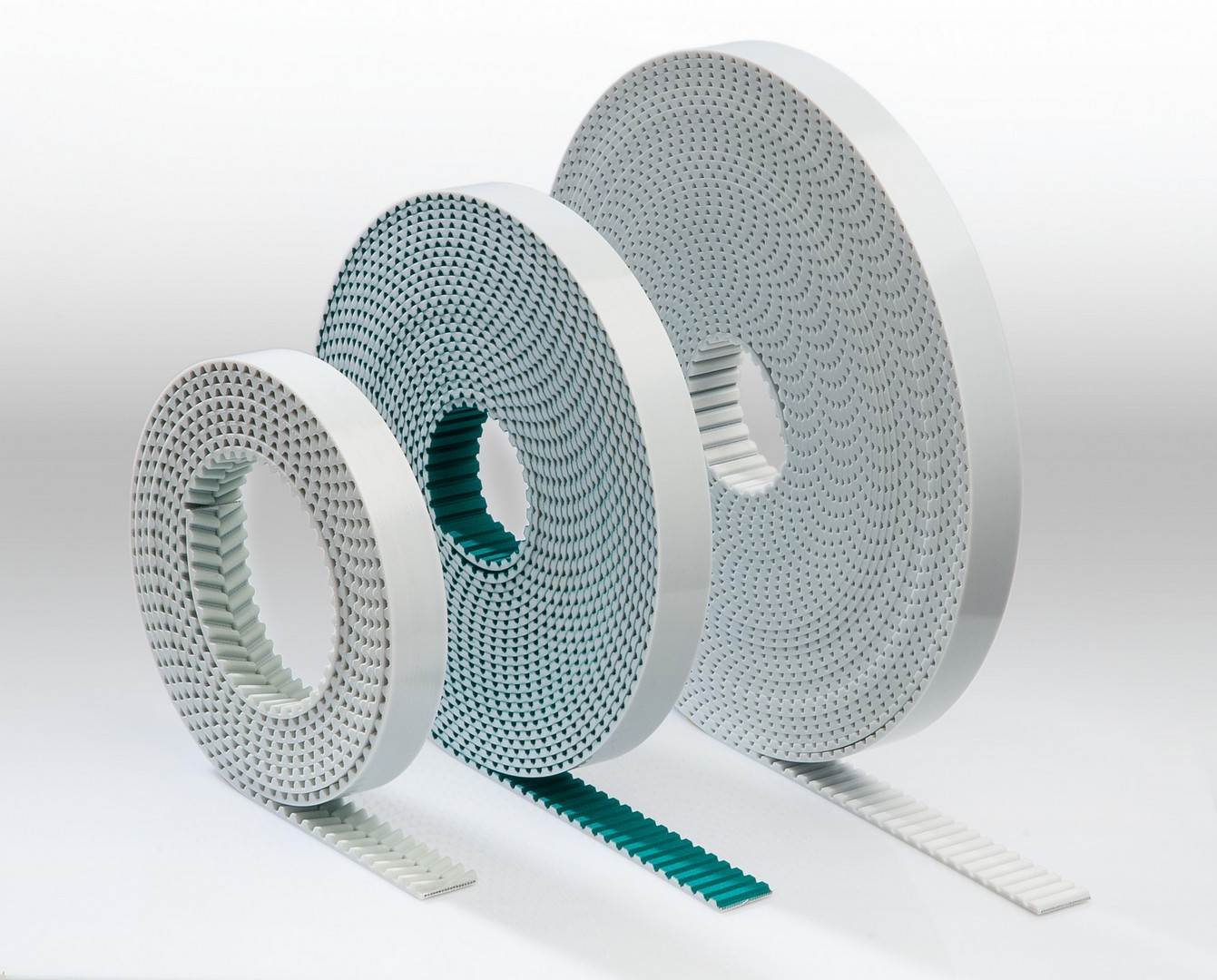

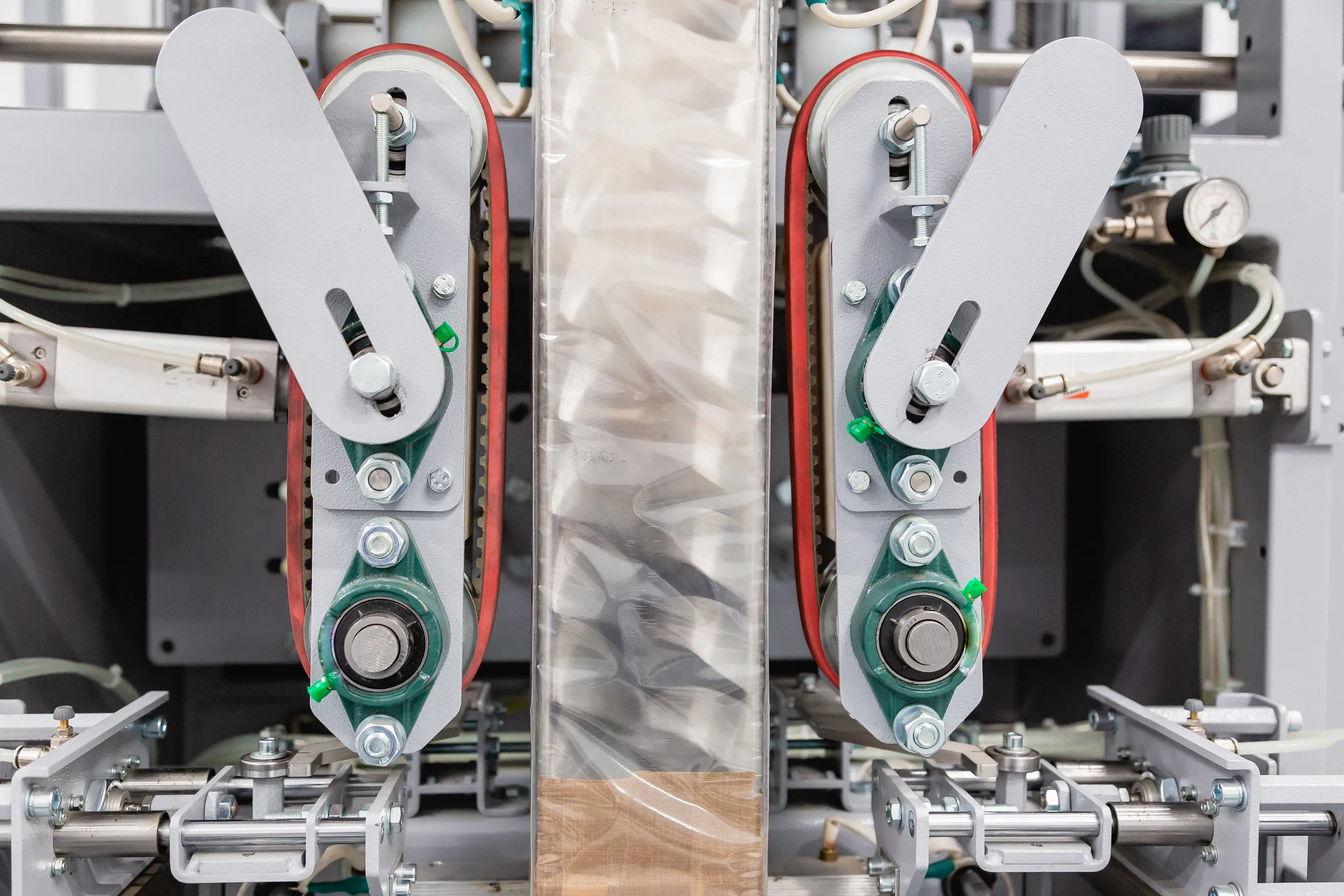

Timing belt transmissions are being used with increasing frequency for internal Conveying by timing belt in, for example, the logistics, food industry and for sorting and packaging machines. Equipped with special coatings and so-called carriers, we can produce timing belts that perfectly match the products and goods you convey internally.

Timing belt drives for conveying

With internal Conveying by timing belt systems, it is important that the system fits well with the characteristics of your product and any requirements from the industry. In addition, we can supply timing belts with properties that ensure a low-maintenance, wear-resistant and low-noise conveying system.

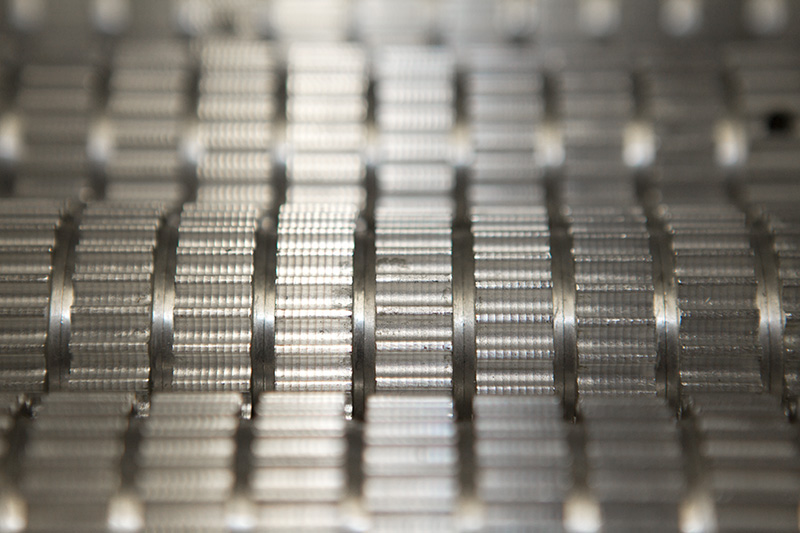

Wear-resistant timing belts with high or low friction coating

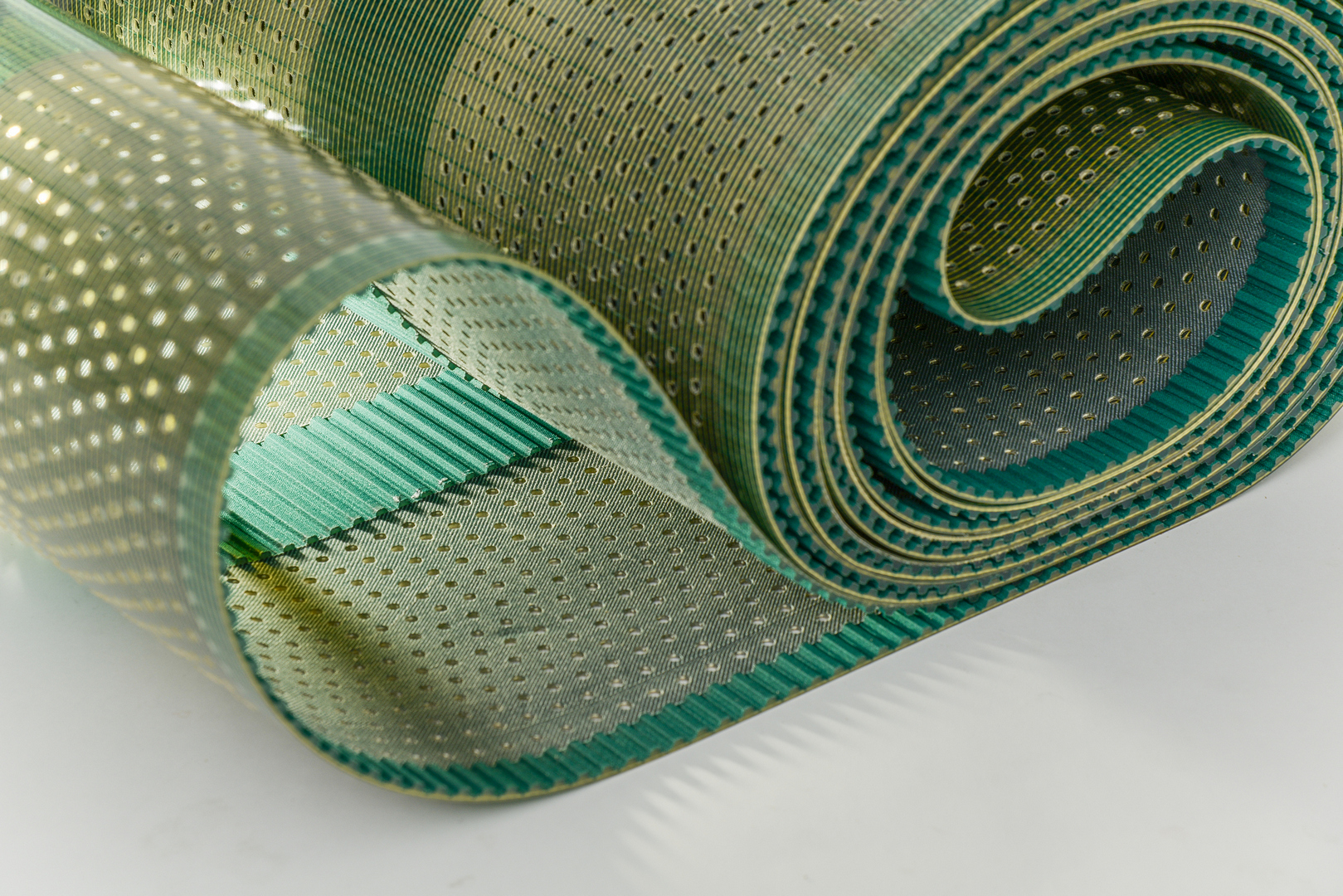

By using various materials such as Linatex or nylon cloth for the covering of the timing belt, we can ensure that at the same time there is high wear resistance as well as a friction coefficient that perfectly matches the functionality of the conveying system.

Various Coatings

Coating method on backing

- Bonding

- Extruded

Coating options

- Rubber (including Linatex, (Lina)trile, Tenax, Natural Rubber)

- PU (glued or extruded in various colors and profiles)

- Grip coatings (e.g. Multigrip, Supergrip)

- Flexible coatings (PU foam, elastomer PU, Porol)

- PVC

- Sillicone top coatings

For a selection with specifications of the various coatings see the attached document with specifications.

If your desired coating is not listed; we have many more options so please feel free to contact us.

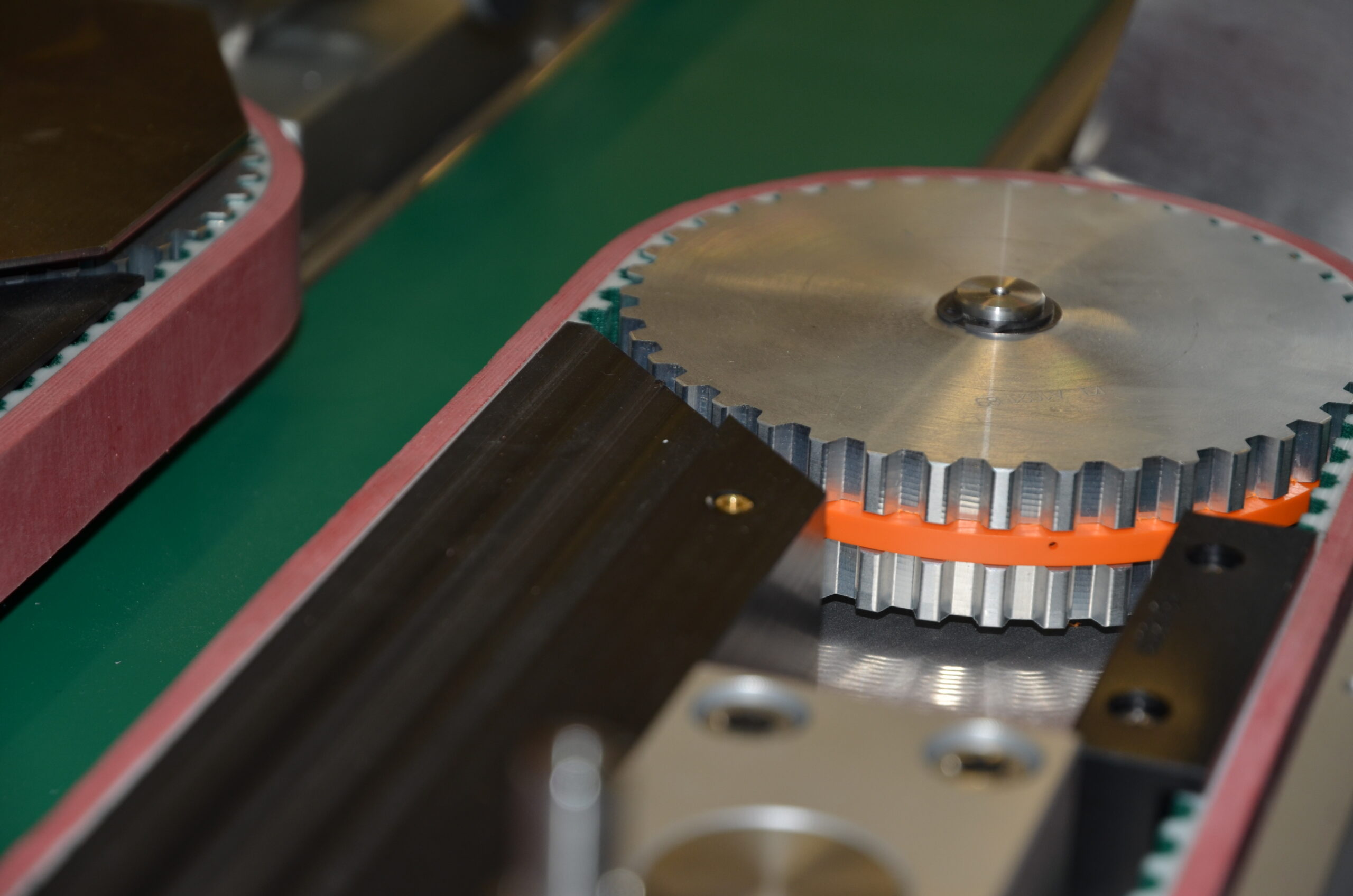

Timing belts for precise Conveying by timing belt

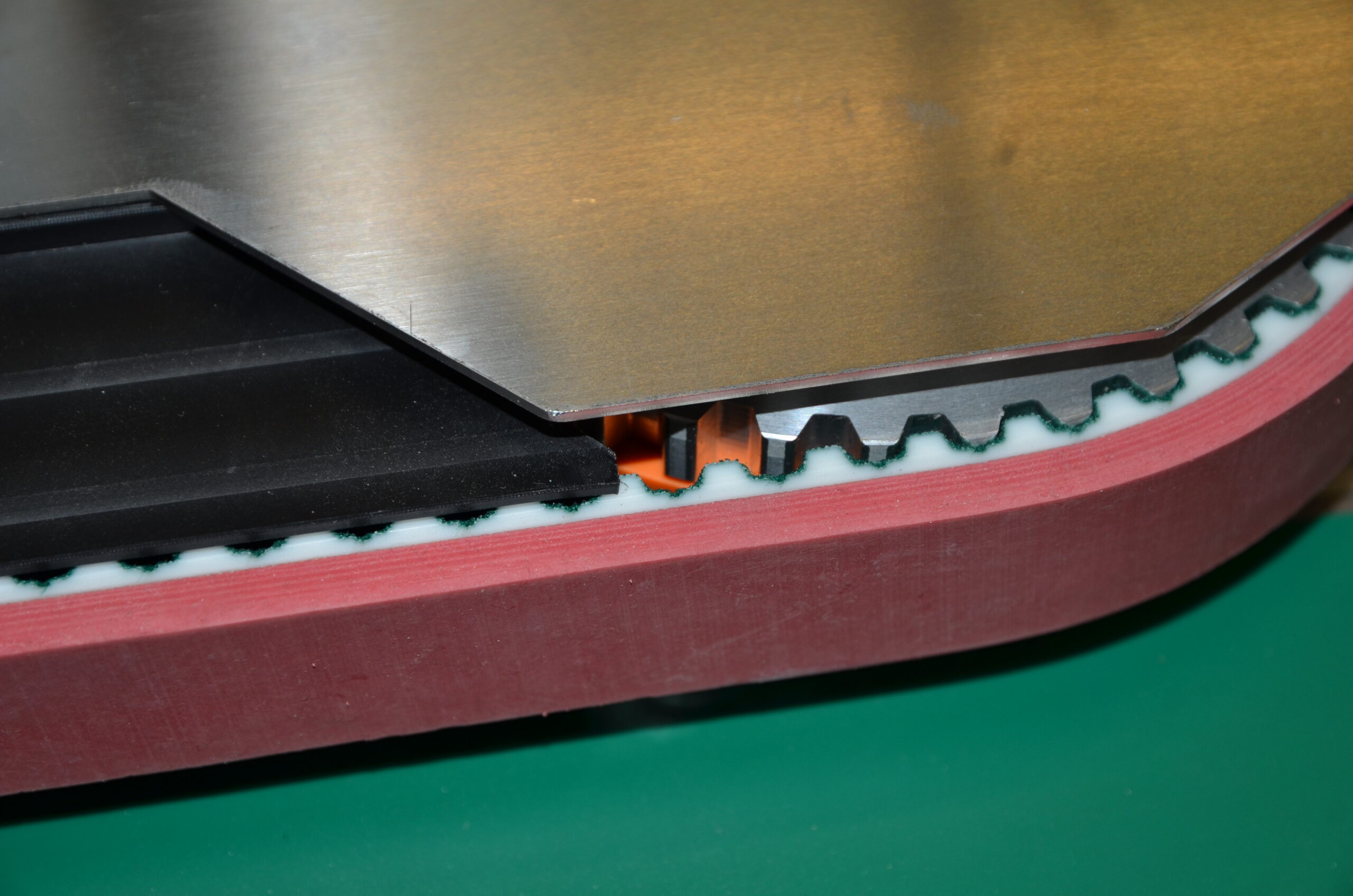

Timing belts can be equipped with so-called carriers with an endless spectrum of operations that make them perfect for conveying goods and semi-finished products. By inserting false teeth in the conveyor belt, these carriers can be made interchangeable for a flexible and adaptable conveying system. We also have extra wide timing belts that can be used, among other things, for internal Conveying by timing belt with precise positioning.

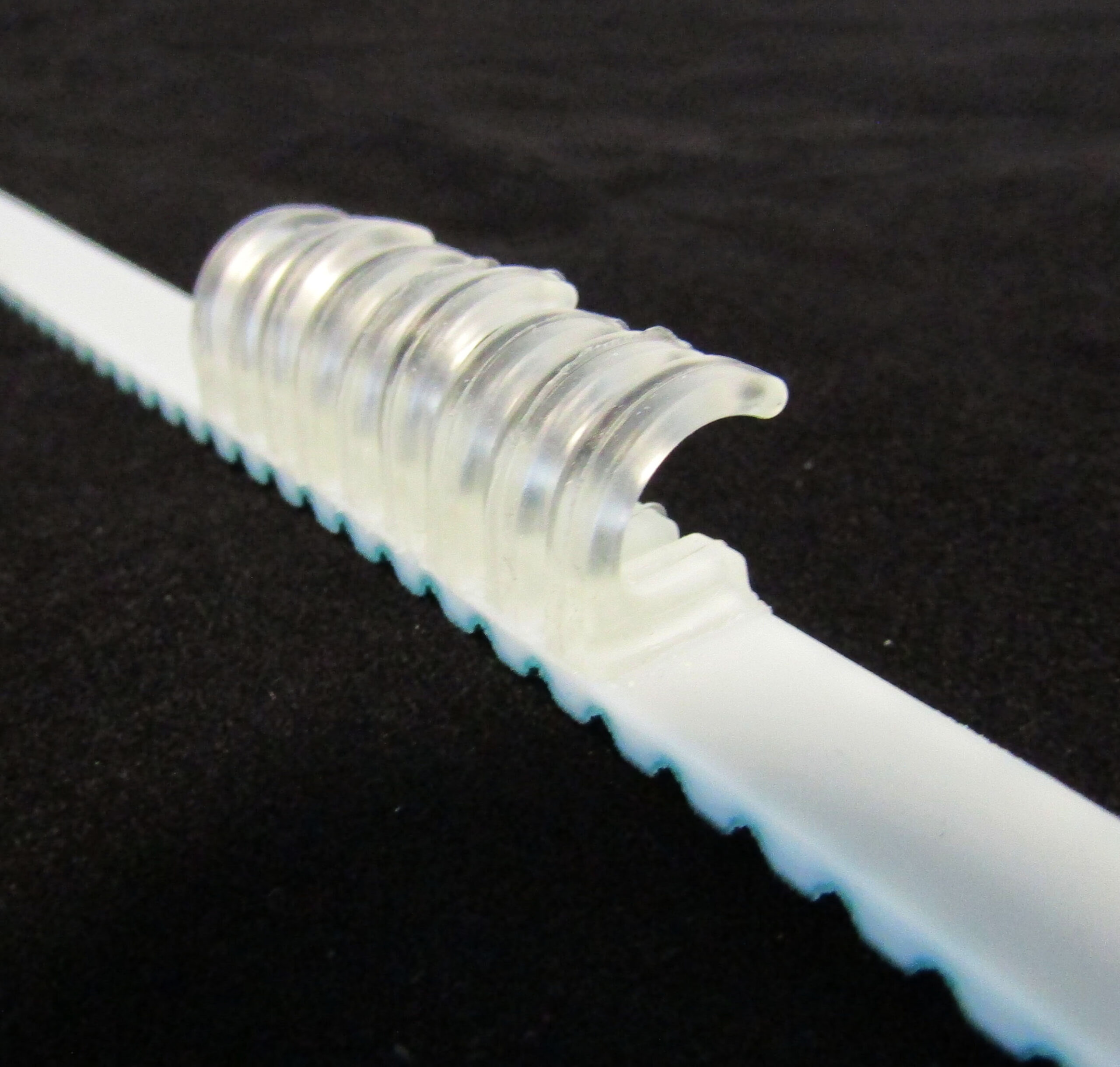

Sliders on back

High-frequency cams can be welded on all thermoplastic PU timing belts. Here there is an extensive series of “standard” available cams, but any desired shape is possible here.

For a selection with specification of the various cams see the attached specification document.

You can also make your own cam and choose a timing belt with a so-called ‘false tooth’; a milled out tooth in the belt that is replaced by a steel, stainless steel or brass tooth with bolt-on options.

If your desired version is not listed; we have many more options so please feel free to contact us.

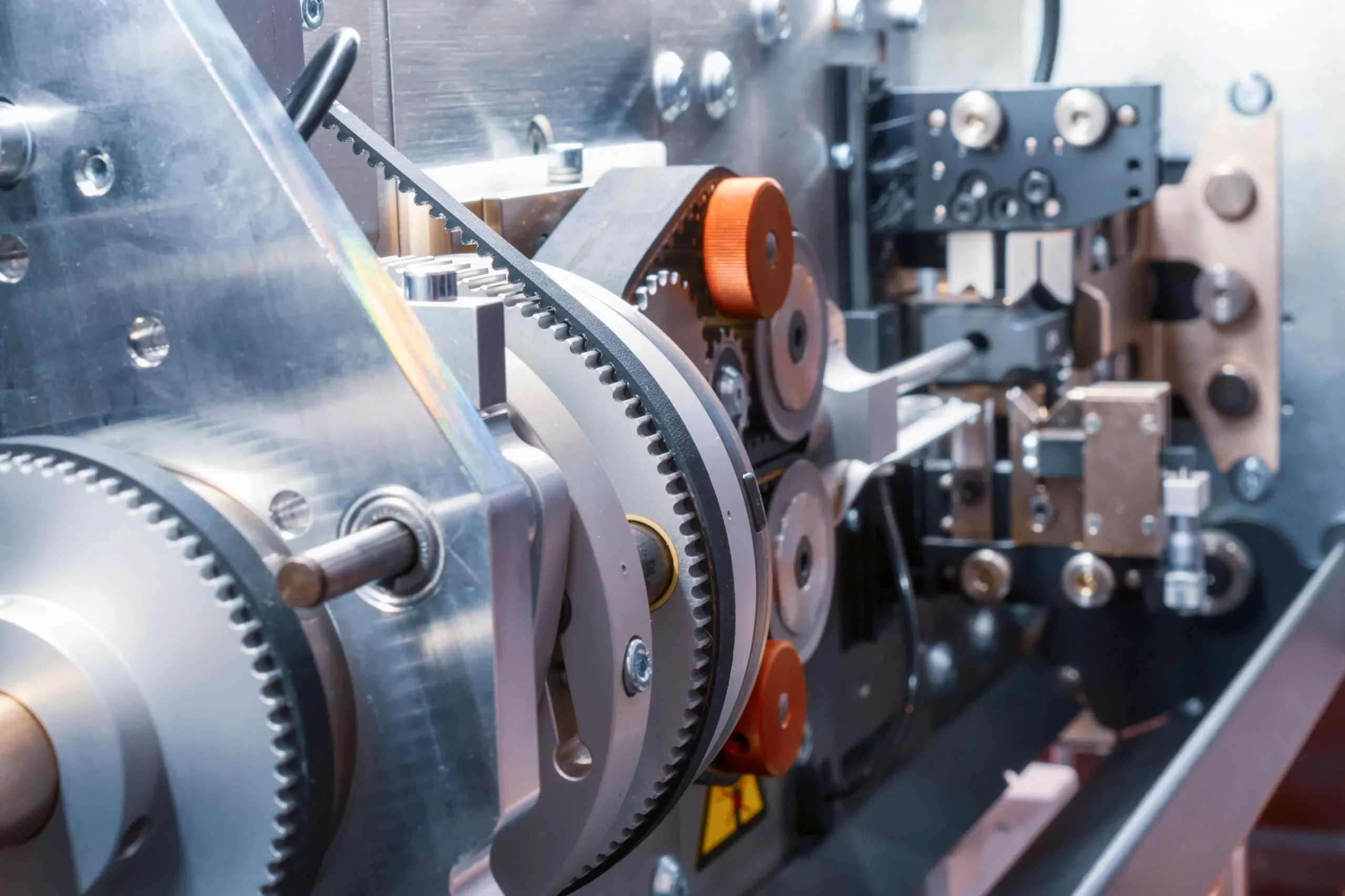

Noiseless, clean and low maintenance

By making the right choice of materials, we provide products and/or materials with optimal Conveying by timing belt. It is also important to make the right material choices when designing in order to achieve systems that are low-noise, easy to keep clean and long-lasting without too much maintenance.

We are happy to work along with you

Finding the right timing belt transmission starts with understanding your issue. After all, there is an optimal timing belt and pulley configuration for every application. By better understanding the intended purpose of the timing belt transmission, we can find the optimal solution for your issue within our endless range of timing belts and pulleys equipped with all possible machining.

Our experienced experts are ready to think with you.

Looking for technical support from our specialist?

Suppliers & Brands

Related Products

Mechanical power transmission

Positioning

Vacuum belts

Special Timing Belt

Caldic Special Pulleys

easy drive Pulleys