Vacuum belts: The essential link in packaging food with plastic films

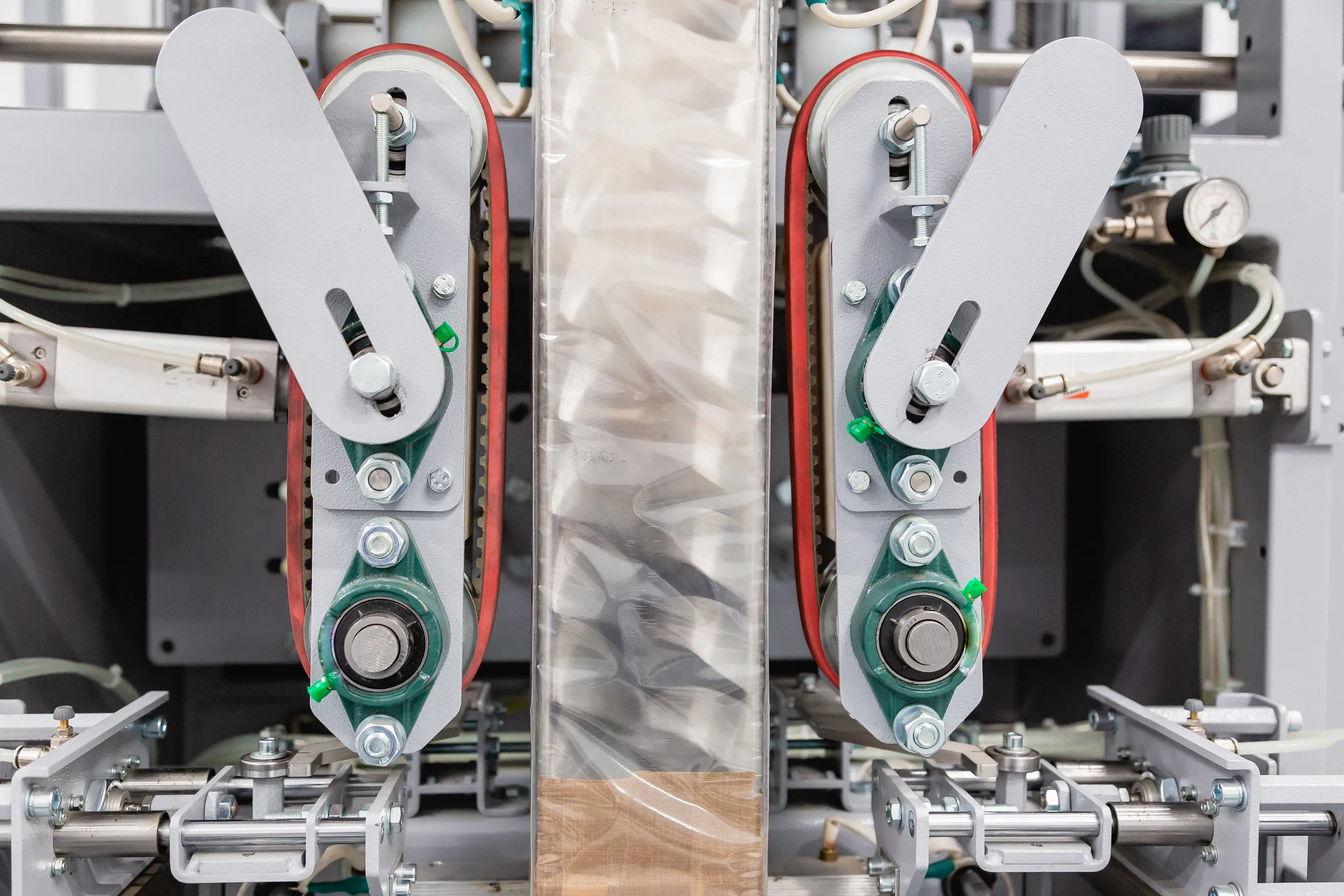

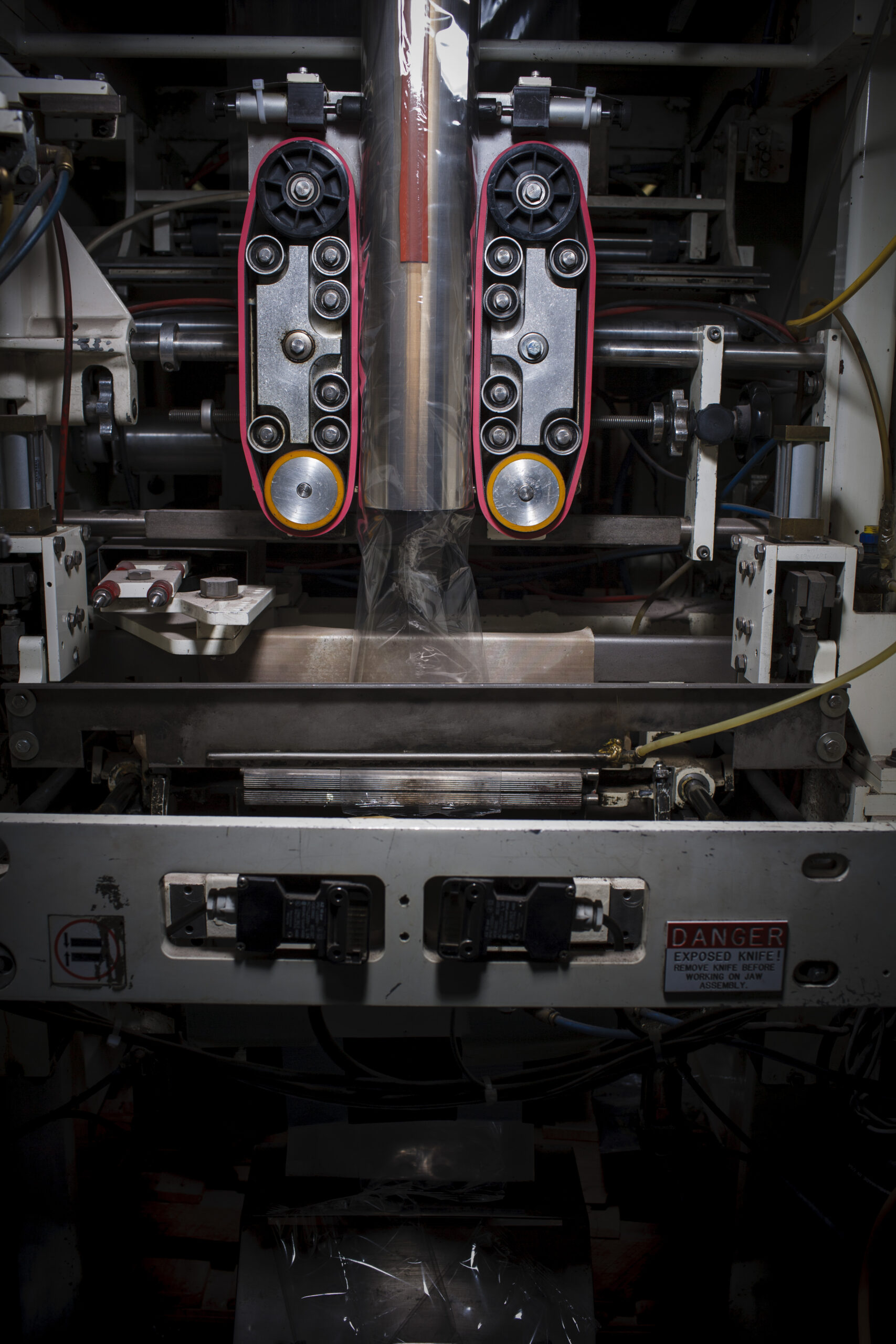

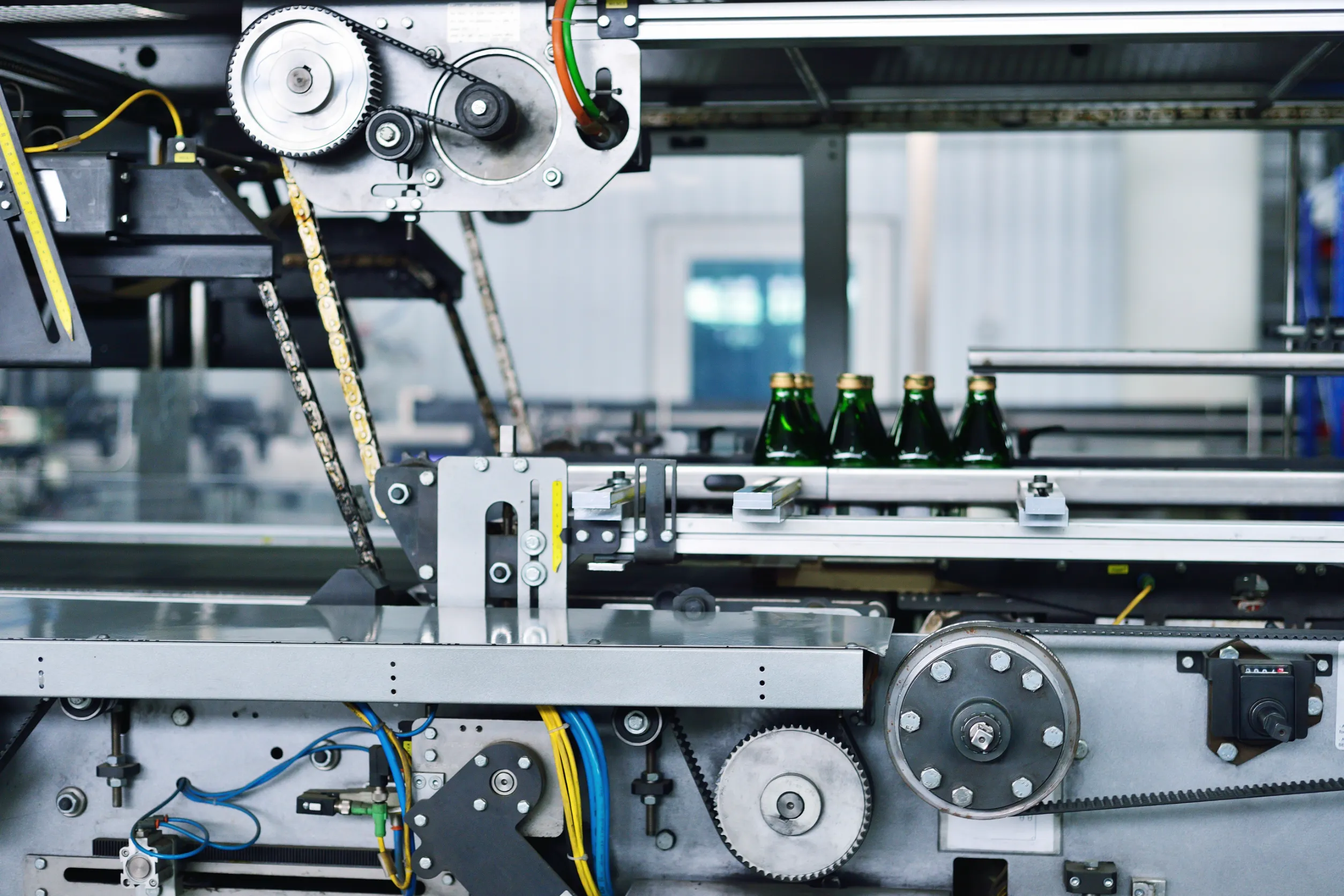

Vacuum belts are an essential component in vertical packaging machines. They ensure a controlled packaging process of various food products, such as vegetables, fruits, pasta and other products.

At Caldic Techniek, we supply vacuum belts of the highest quality, specially designed to ensure optimal performance and increase efficiency in your packaging process.

What are vacuum belts and how do they work?

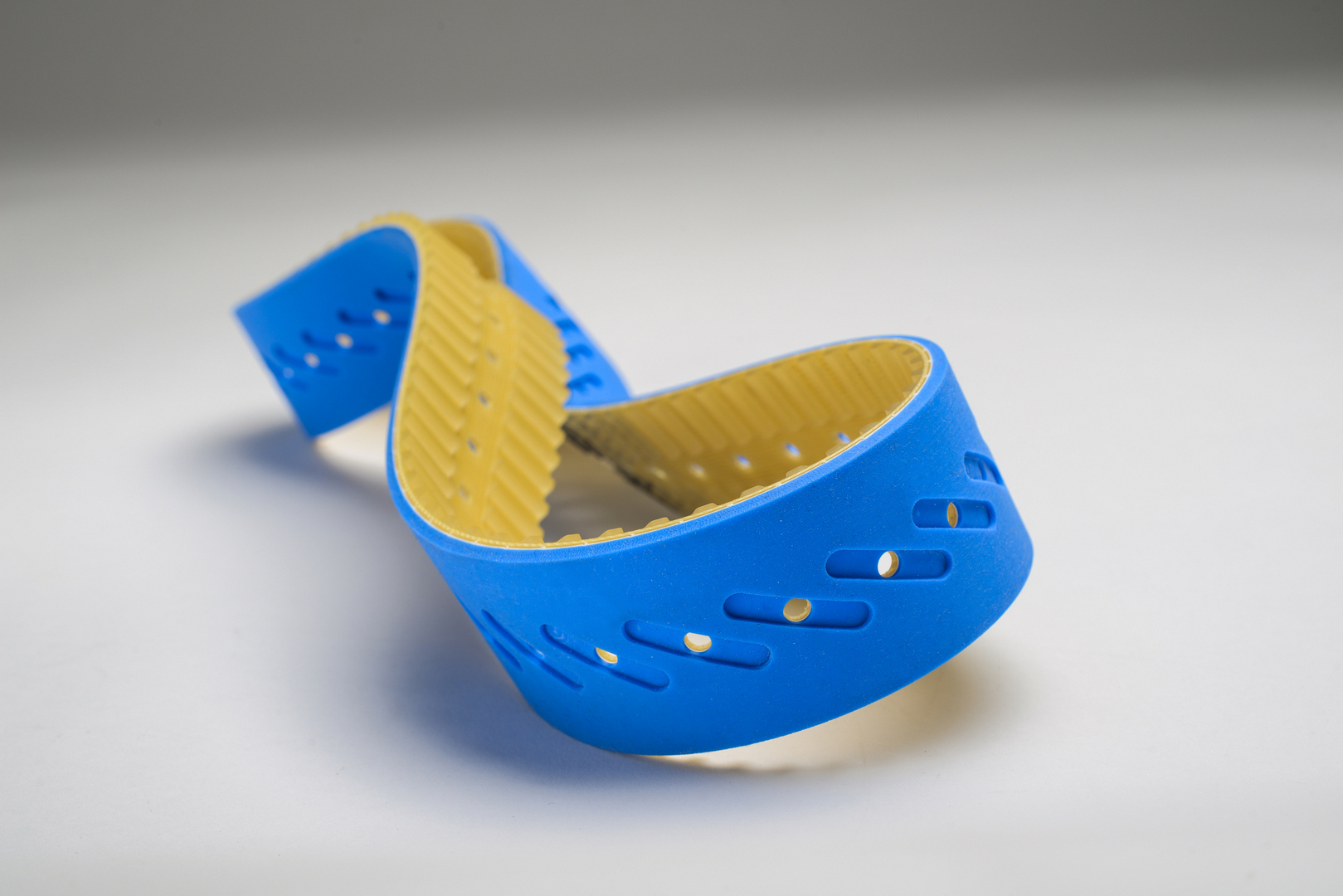

A vacuum belt is a timing belt with a friction coating on the back of the belt and equipped with vacuum holes. The packaging film is drawn against the friction coating by means of negative pressure (vacuum). This technology ensures that the film is transported through the machine in a controlled manner, where it is filled with the respective product and then perfectly sealed.

Application in the food industry

Packaging food in bags, is almost unthinkable today. Vacuum belts in vertical packaging machines are widely used for packaging various types of food in film packaging, such as:

- Pasta products: such as spaghetti, tortellini and fusilli.

- Fruit and vegetables: from peppers to tomatoes and leafy vegetables.

- Frozen products: ranging from frozen vegetables to ready-to-eat meals.

- Processed meats: such as sliced meats and sausages.

- Snacks; from candy to chips, as well as cubes of cheese and nuts.

Benefits of vacuum belts at Caldic Techniek

Our vacuum belts are developed with a focus on durability and efficiency. They offer numerous benefits for products in the food industry:

• High precision

Thanks to our wide range of friction coatings, tailored to the specific application, an optimal grip is created between the film and the belt. This ensures stable and accurate positioning of the film in the machine, even with minimal vacuum.

• Energy and noise reduction

Our vacuum belts feature precision ground vacuum grooves according to the latest technology. This minimizes vacuum loss, requiring a lower vacuum level to effectively transport the film. This leads to energy savings and less noise during the packaging process.

• Hygienic design

Our belts are easy to clean and can be supplied with a white FDA-approved coating or a blue silicone coating, which meets the strict hygiene requirements of the food industry.

• Minimum downtime

By using materials such as Durataq friction coating, for example, our vacuum belts offer a long service life while maintaining grip between the belt and film. This minimizes maintenance requirements and increases packaging line uptime.

Innovation and customized solutions

At Caldic Techniek, we understand that every Machine Builder and food manufacturer has unique requirements for their packaging process. That’s why we offer custom vacuum belt solutions, fully tailored to your production needs we deliver the right vacuum belt for every application.

Why choose Caldic Techniek?

With our in-depth knowledge of timing belts and vacuum technology, Caldic Techniek offers more than just high-quality products. We also provide expert advice and comprehensive technical support to optimize your production process. The proper use of vacuum belt can not only make your packaging line more efficient, but also minimize food waste and downtime.

Wondering how our vacuum belts can improve your packaging process? Contact us today for a no-obligation consultation.

Questions about the possibilities with our vacuum belts?

Suppliers & Brands

Related Products

Drive Technology

Timing belt transmissions