Rexnord 1104 Series: Innovative Conveyor Belt Solution for the Beverage Industry

The Rexnord 1104 series of modular conveyors offers an innovative combination of stability and cleanability, making it an advanced solution for conveying challenges in the beverage industry, among others.

For two years, we have successfully applied this series in various customer engineering applications, proving time and again that the unique combination of FlatTop and FlushGrid tires results in a versatile and efficient solution.

Challenge: Improved Stability and Hygiene in the Beverage Industry

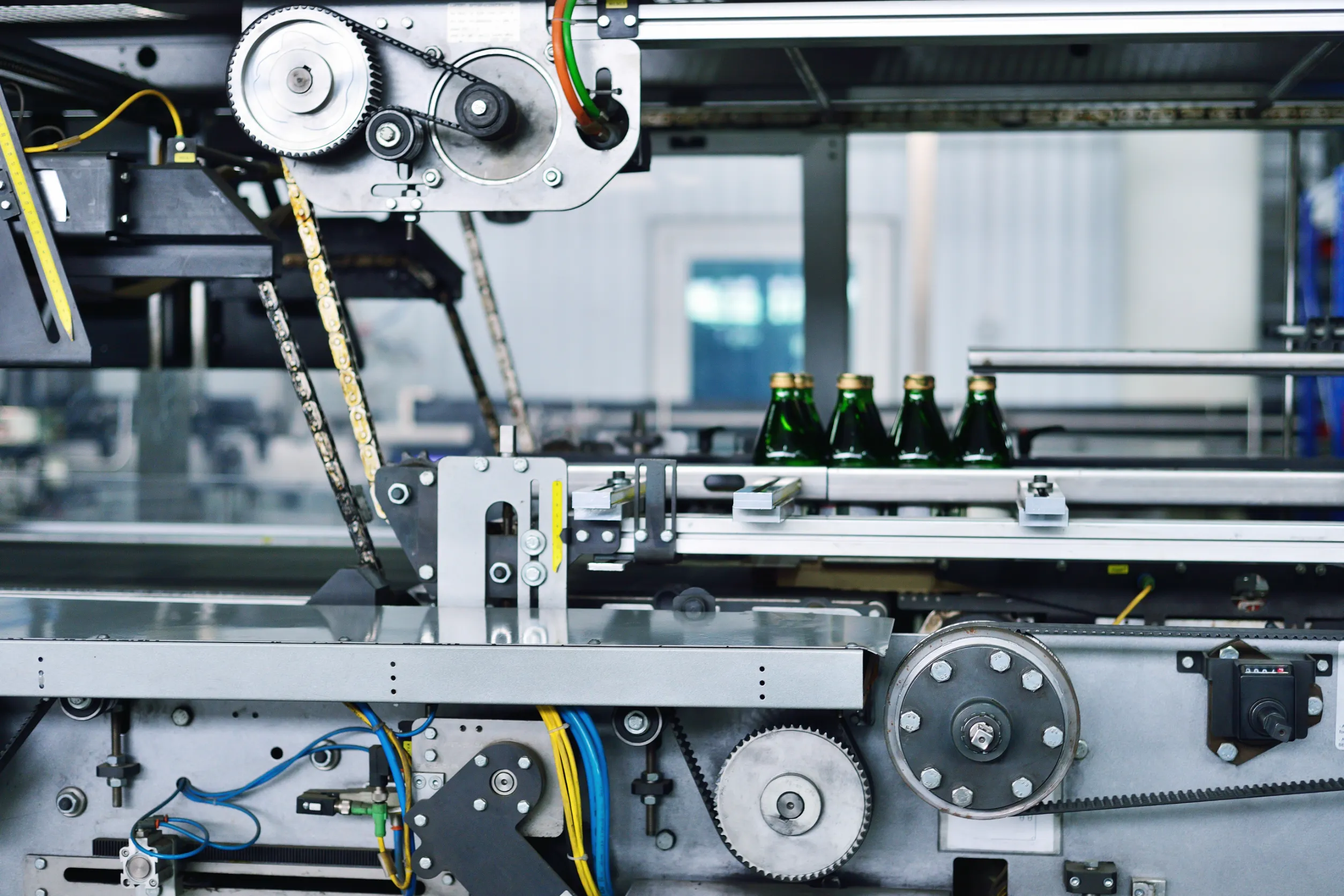

Within the beverage industry, the demand for stable and hygienic conveying solutions is high. Conveyors must not only ensure reliable and safe movement of products such as aluminum cans, glass and PET bottles, but also be easy to clean to ensure high hygiene standards and low friction. Traditional belts cannot provide sufficient stability, leading to toppled products, and often suffer from high friction or difficult cleanability. The industry is looking for modular belts that address these challenges resulting in improved hygiene and product stability.

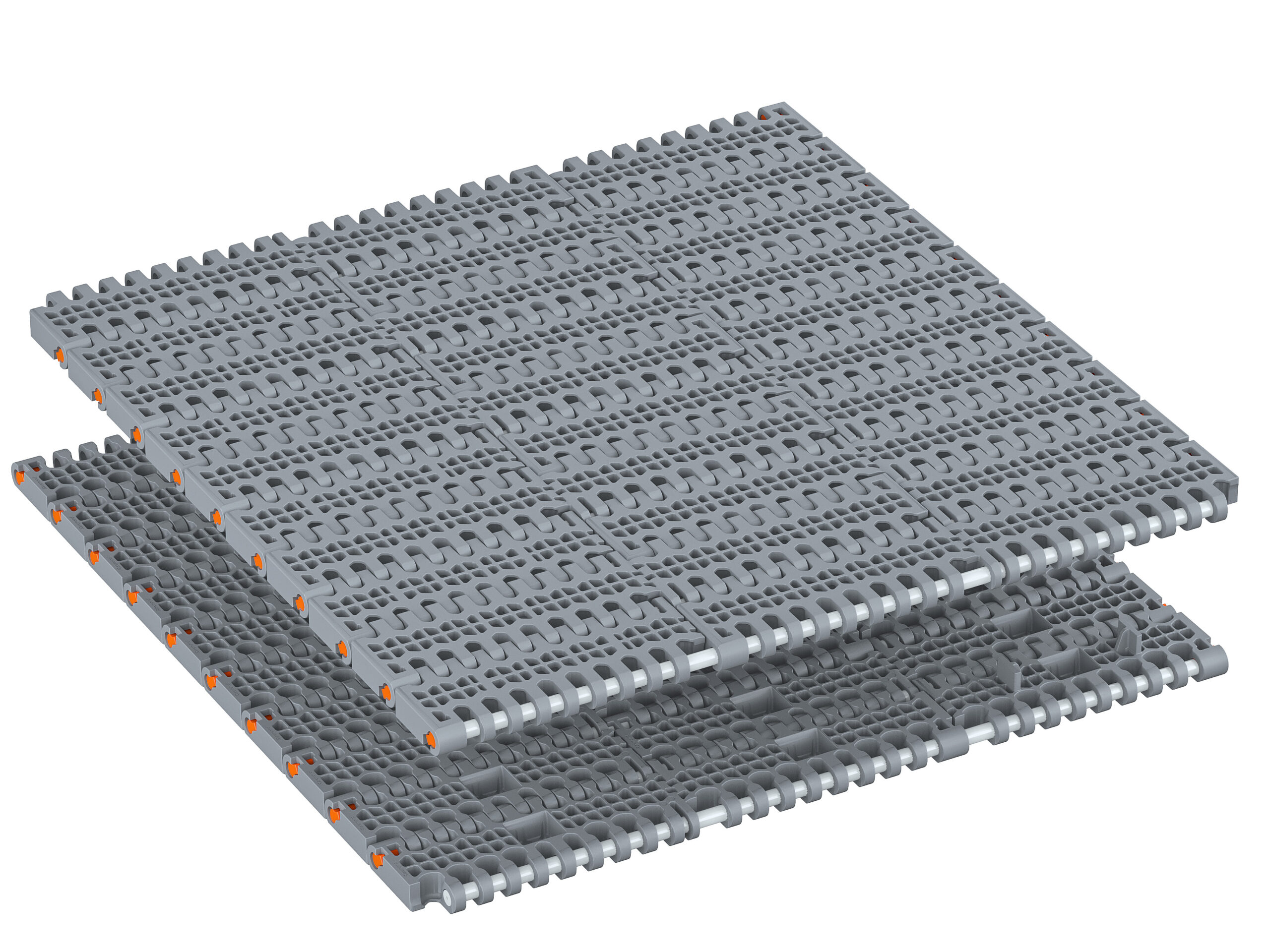

Specialized Parts for Modular Conveyors: The 1104 FlushTop Series

The Rexnord 1104 FlushTop series was developed in response to these challenges. Combining the stability of the FlatTop surface with the cleanability of the FlushGrid chain, the 1104 series offers a solution ideal for the beverage industry. The belt is designed to safely and stably transport aluminum cans, glass bottles and PET bottles, among others, with minimal friction and maximum cleanability. This modular belt is therefore ideally suited for dry running applications when properly cleaned.

Benefits of the Rexnord FlushTop 1104 Series

1. Optimal Product Stability

Thanks to the small openings in the belt, the product is supported as well as it would be on a FlatTop belt, resulting in less downtime due to toppled products. This contributes to a more efficient production line and less product waste.

2. Improved Hygiene

The open structure of the belt allows dirt and water to drain easily. This makes the 1104 series easy to clean, keeping friction low and contributing to improved hygiene standards in the production line.

3. Higher Production Output

The use of PSX material and the dirt-draining structure of the belt ensure a permanently low coefficient of friction. As a result, products such as cans and bottles are better guided through the production line, resulting in higher production output.

4. Lower Inventory Costs

Thanks to the standardization of the 1104 series, the number of different conveyors in production lines can be reduced.This simplifies maintenance and reduces inventory costs, as one belt now offers the functionality of both FlatTop and FlushGrid surfaces.

Applications of the 1104 Series

The Rexnord 1104 FlushTop series is particularly suitable for applications within the beverage industry, where high product stability combined with low friction are critical. However, the versatility of the design also makes the belt applicable in other industries where similar demands are placed on conveying solutions.

Want to know more about the Rexnord 1104 Serie?

Do you have questions about how Rexnord 1104 series conveyors can optimize your production line? Feel free to contact us! Our specialists are ready to advise you and together find the best solution for your specific issues.

Questions about the possibilities with the Flushtop from Rexnord?

Suppliers & Brands

Downloads

Related Products

Drive Technology

Conveyors