Special pulley for chocolate production line

One of our clients supplies and maintains machinery and parts for a company that processes chocolate

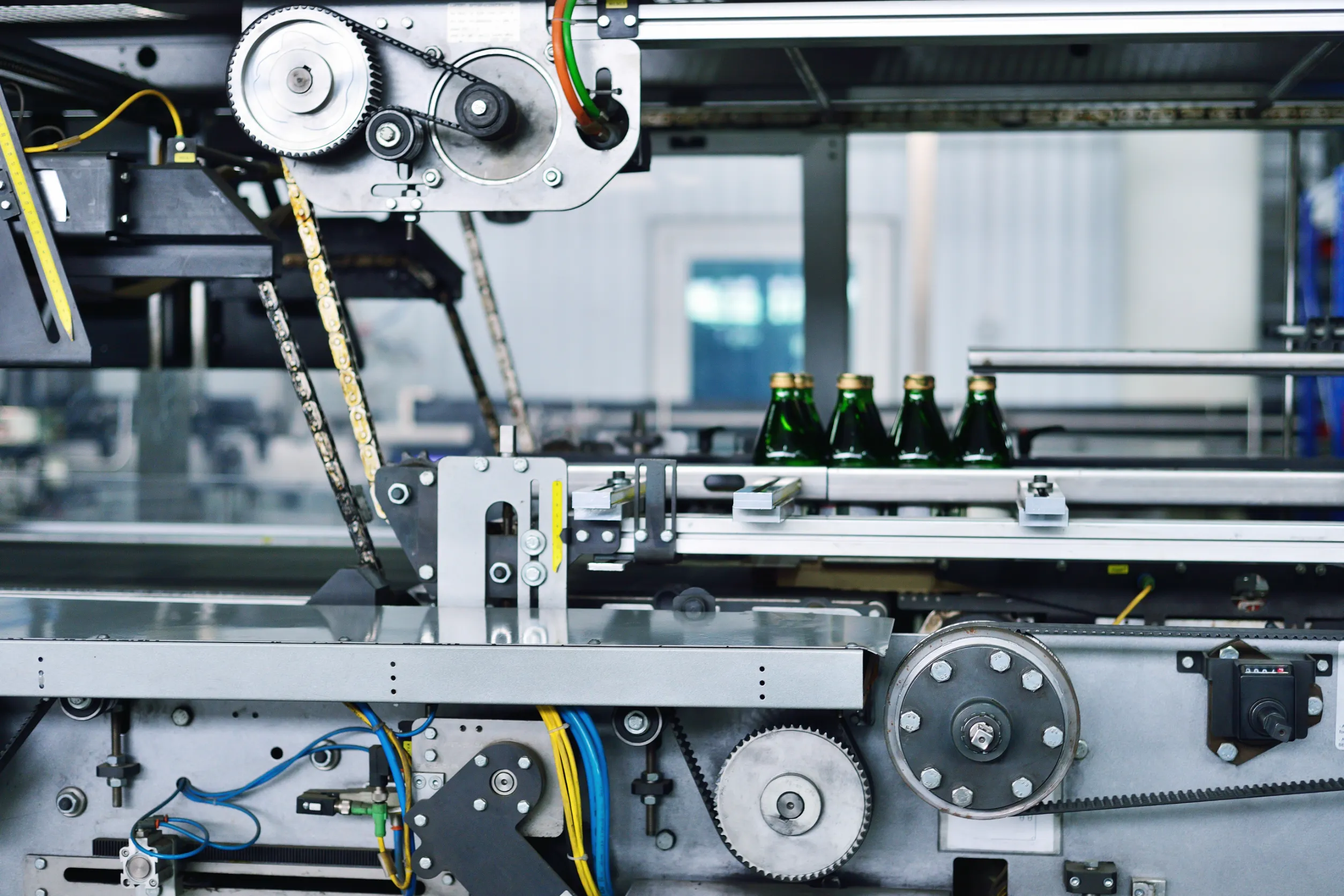

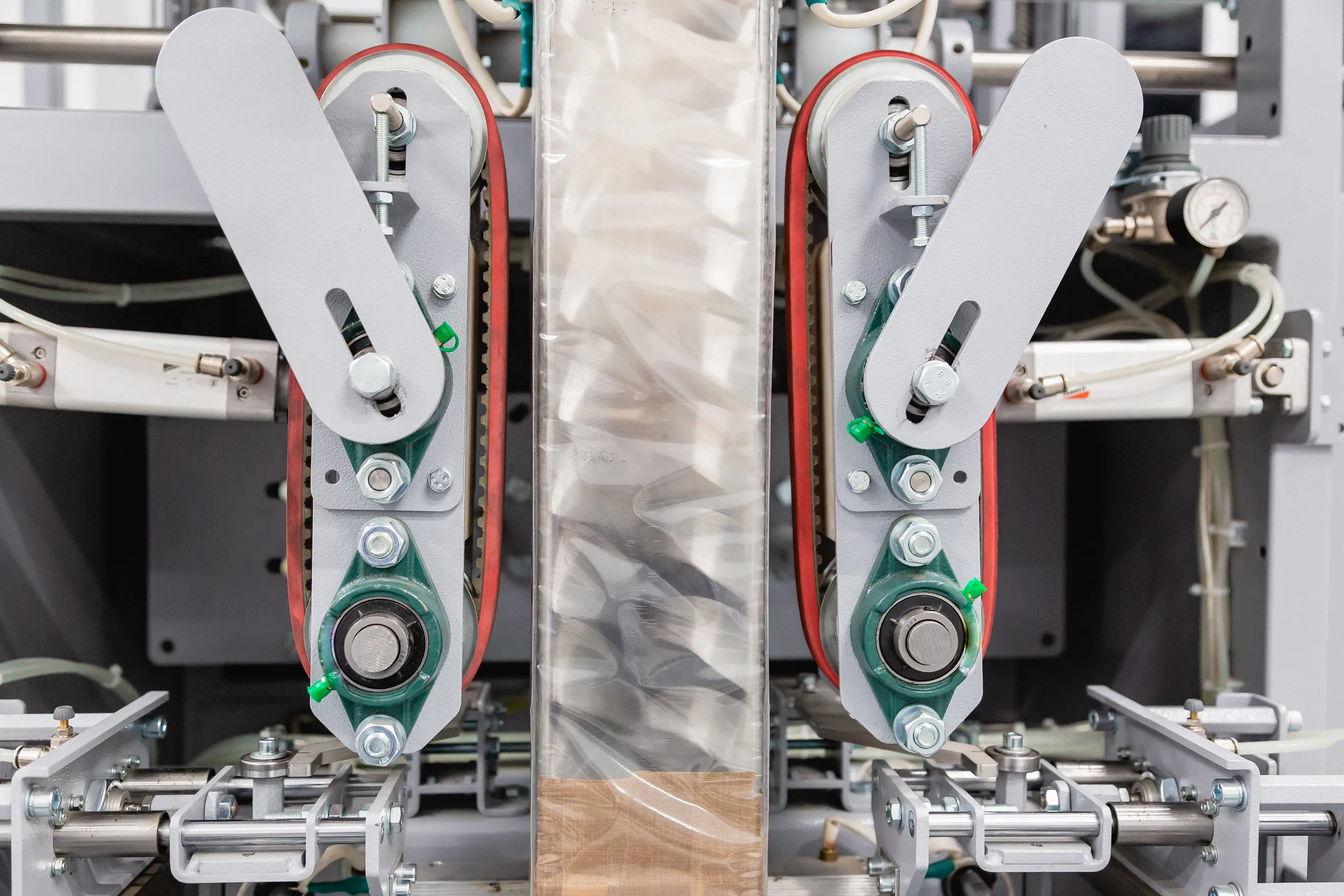

This chocolate machine builder reported to us with a recurring problem: on one of the production lines, a coating of liquid chocolate is applied which solidifies within a short time after application. The undesired effect of this was that the liquid chocolate also ended up on the pulleys, among other things, which, due to solidification, led to the pulleys’ diameter increasing and the eventual breaking of the transport timing belt.

Since the initial solution, performing regular and thorough cleaning, led to frequent production shutdowns, we worked with our customer to find an alternative.

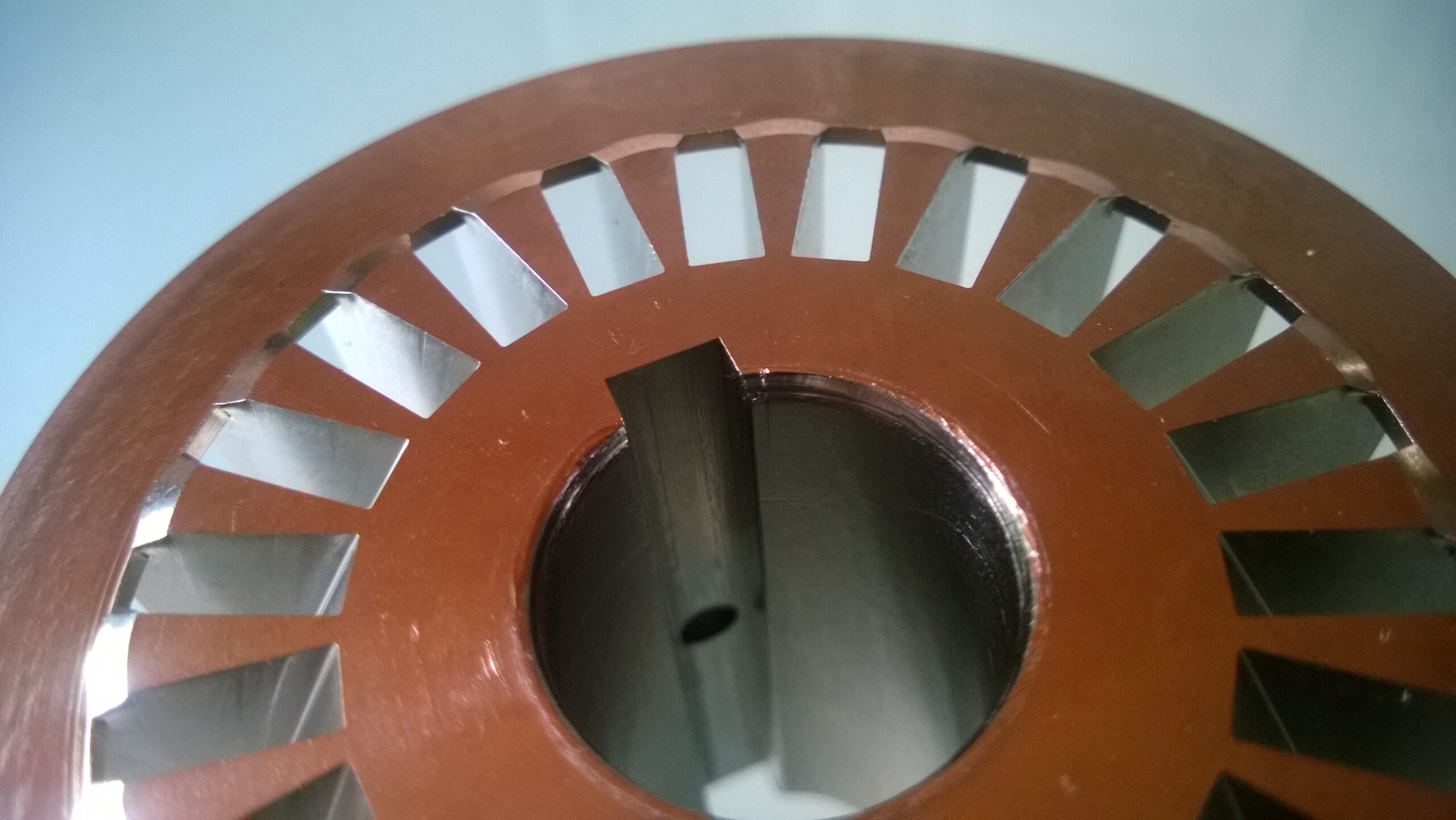

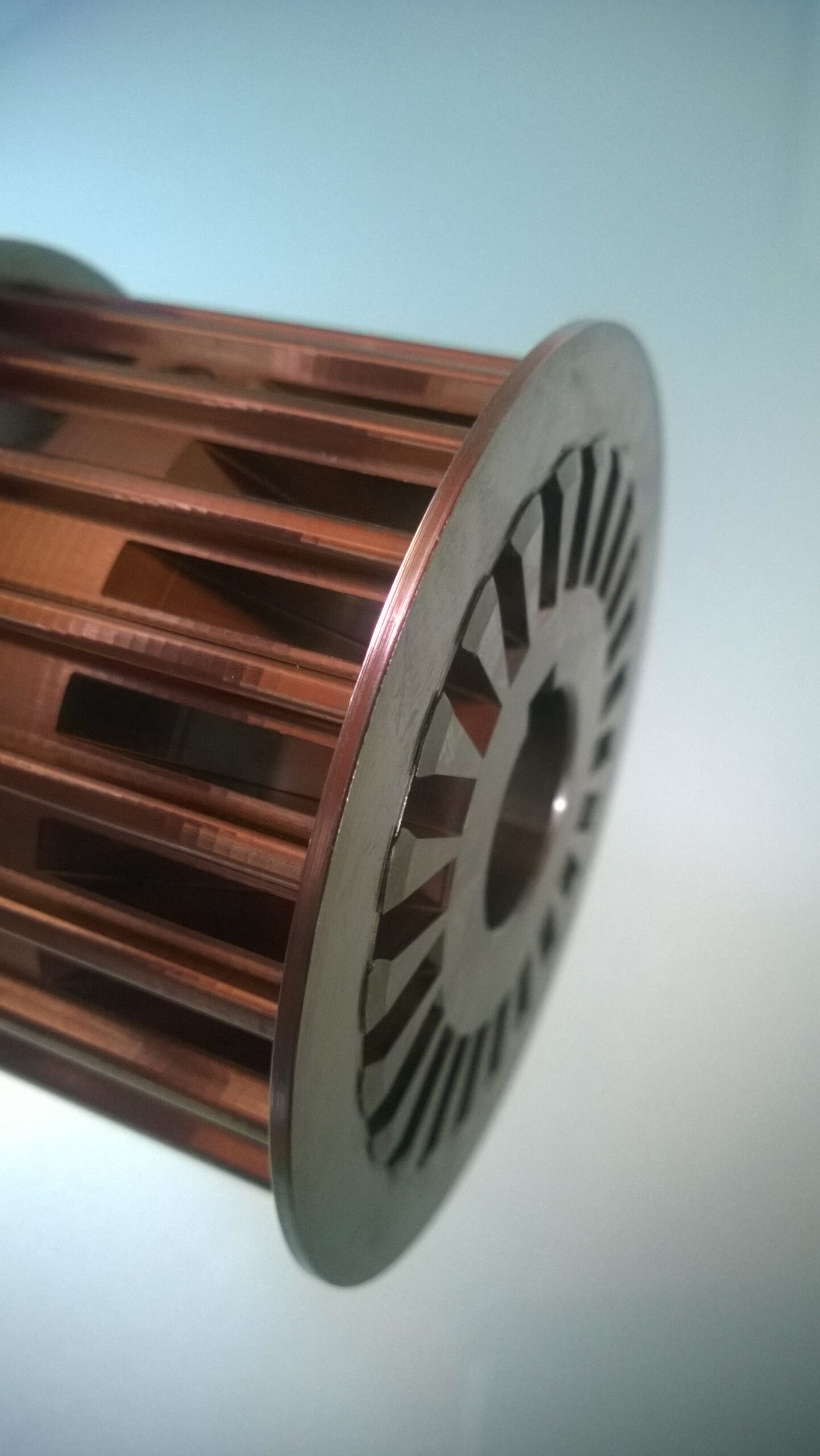

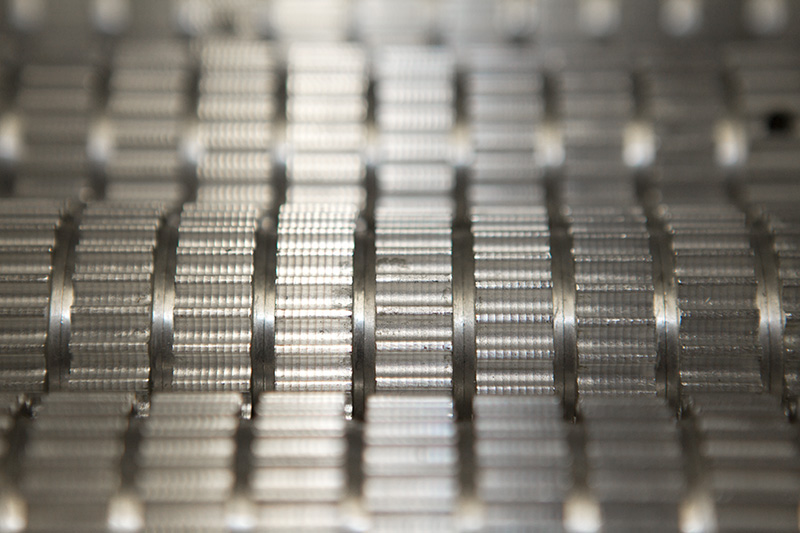

The chocolate pulley

Together with the customer, we developed a solution that succeeded in solving the problems and minimizing the downtime of the production line for maintenance and cleaning. The said solution consists of inserting slots between the teeth. These slots allow the toothed belt to push the chocolate away at the moment it is just short of solidification. Thus, the chocolate no longer remains between the gears of the pulley and no additional cleaning or maintenance stops need to be inserted.

The final solution we developed together with the customer not only leads to the timing belts remaining whole. The new pulleys made it possible to reduce costs and increase production capacity.

Customized solutions in cooperation with Caldic Techniek

Only through close cooperation between the customer and our experts is it possible to design and develop such customized solutions. With our extensive experience, we are able to apply our knowledge of products and their capabilities to various production and transport processes. Here a dedicated contribution from the customer is essential. Only by applying our joint knowledge and experience to challenges in production processes do we arrive at solutions that can lead to major benefits in practice.

Do you also have a challenge in the area of pulleys or timing belts? We are happy to look together with you at the possibilities of improving your production and transport processes through our customized solutions.

Caldic Techniek adds value to your business

We believe it is important to add value throughout the chain. To this end, we have developed various services that you can rely on.

During your engineering process, our people will advise and assist you. Because the better solution may require customization, we have the ability in our workshops in Rotterdam to modify generators and produce toothed belt pulleys entirely according to your specifications.

Would you like to know more about our CNC pulley production? We would be happy to tell you more about the various possibilities with our proprietary pulleys.

Questions about Caldic's in-house CNC Pulley production?

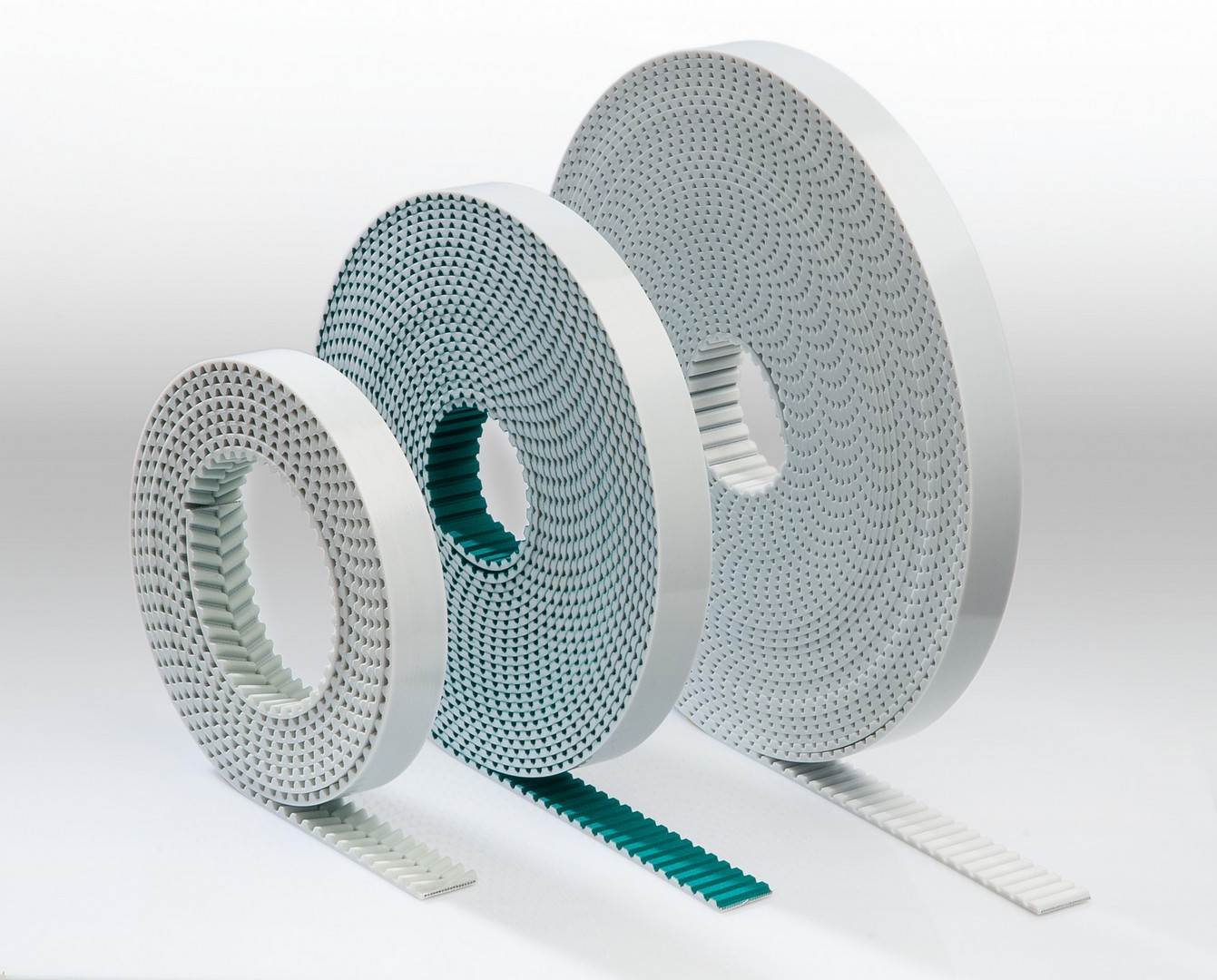

Related Products

Drive Technology

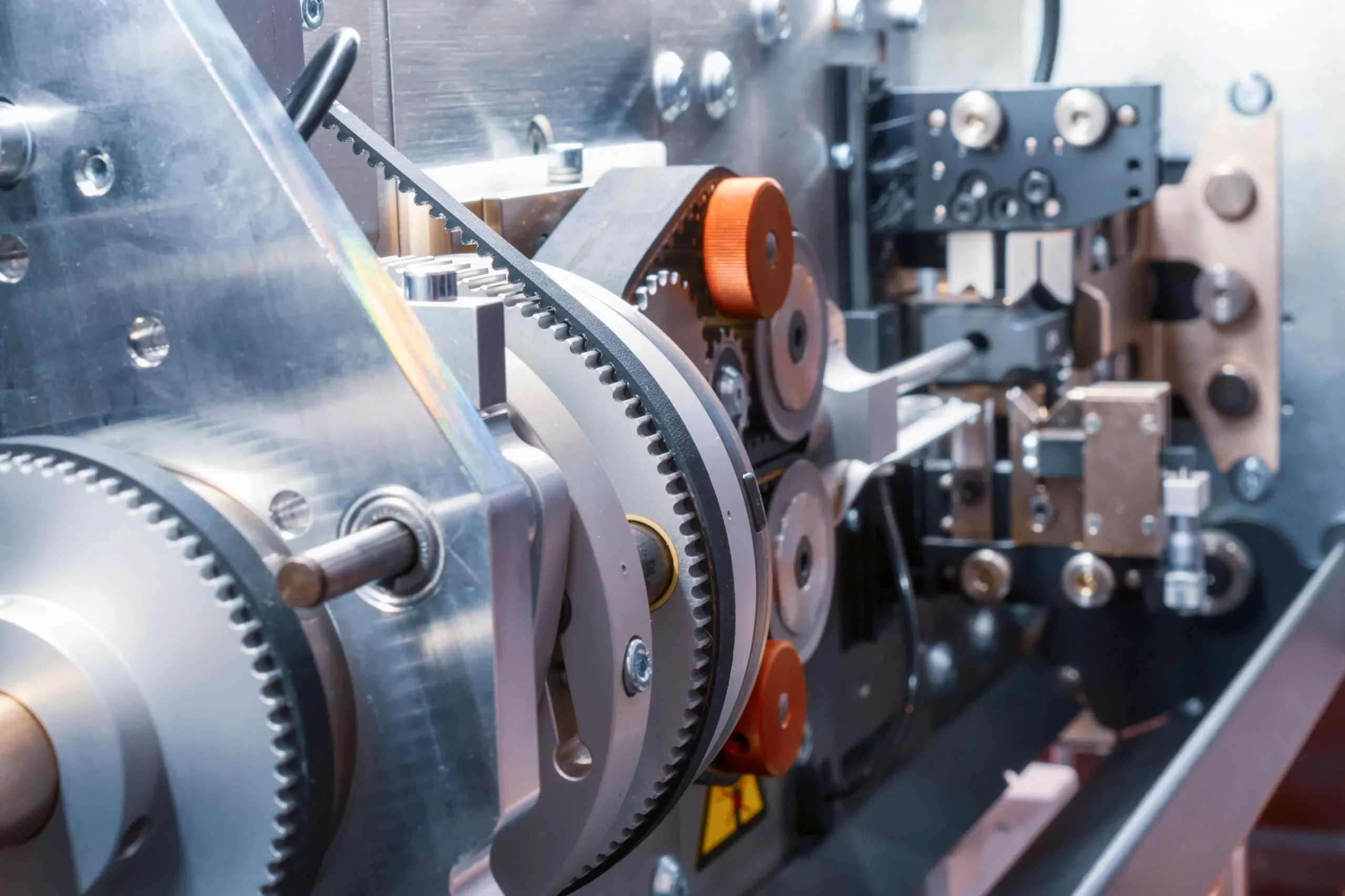

Timing belt transmissions

Mechanical power transmission

Positioning

Conveying by timing belt

Vacuum belts

Special Timing Belt

Caldic Special Pulleys

easy drive Pulleys

Standard Pulleys