The right choice for your conveyor type

When assembling a conveyor, choosing the right conveyor type is crucial for an optimal end result.

A wide variety of conveyors exist, including fabric belts, flaatop chains, modular belts, rollers, magnetic systems, conveyor chains and timing belts. Each with unique characteristics that determine the best choice in your specific application.

Important factors in this choice include:

- Transport speed

- Positioning accuracy

- Contact surface with the product

- Cleanability

- Carrying capacity

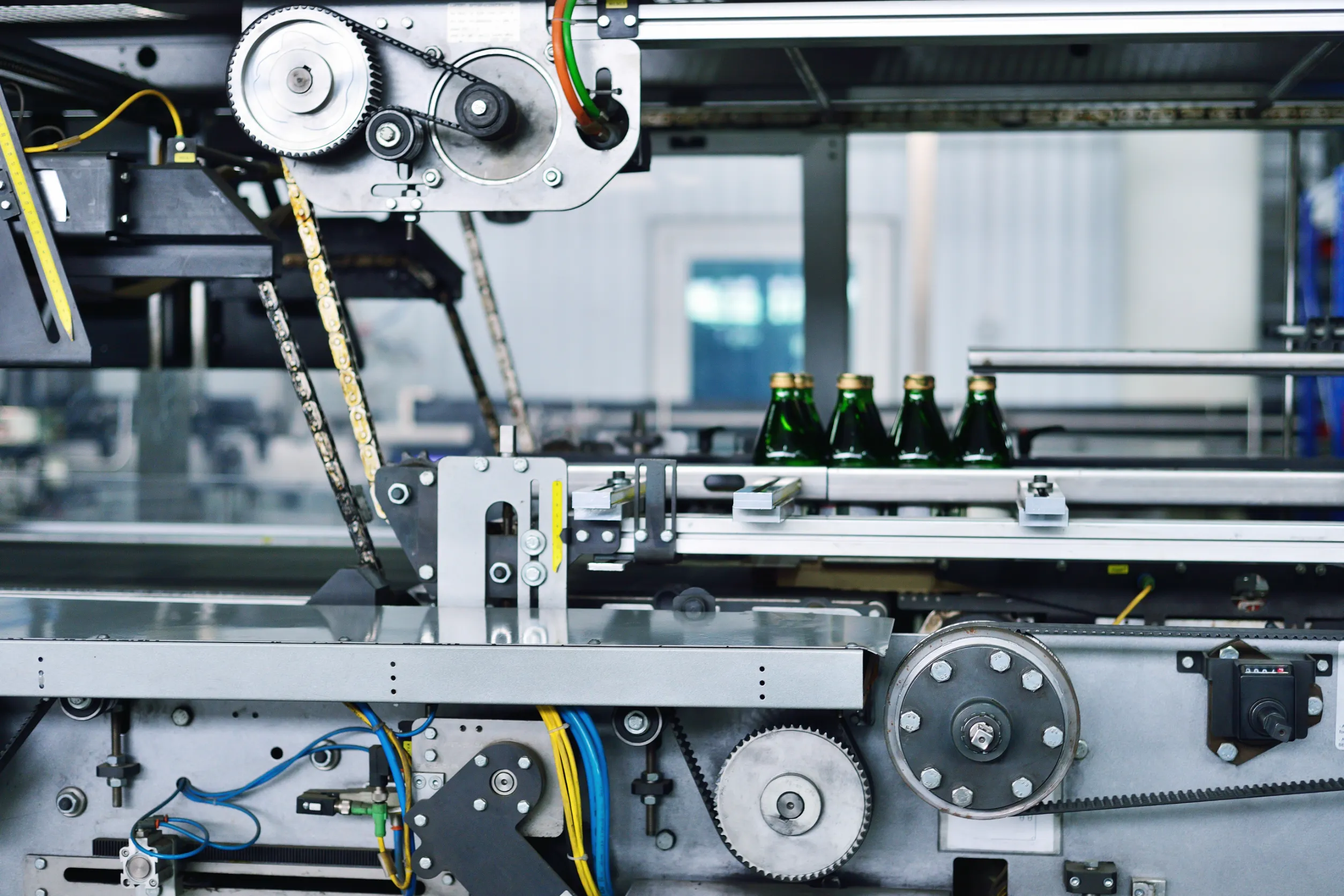

Conveyor with wide timing belt solution

An intelligent solution within conveyor belts is the use of timing belts. This type of conveyor offers numerous advantages, including:

- Controlled and precise drive

- High dynamic behavior, suitable for precise applications

- Clean operation without the need for lubrication

- Possibility of a width of 500 mm

- Minimal stretch, achieving high positioning accuracy

Toothed belts are widely used for applications where precision and reliability are required. Thanks to a wide range of coatings and carriers/cams, the applicability of these belts is very versatile. Standard timing belts are typically produced to a maximum width of 150 mm, but within our Megadyne and Elatech product range we offer timing belts up to 500 mm wide. This makes them ideal for controlled conveying systems.

Characteristics of our wide timing belts

- Available in T5 and T10 profiles

- Transparent PU construction

- Kevlar cords (optional steel)

- Nylon coating possible on back and tooth sides

High positioning accuracy

Thanks to the drawstrings in the timing belts, they offer exceptionally high positioning accuracy. This makes them ideally suited for applications requiring precise feeding of products.

Reducing cupping effect with wide belts

A common phenomenon with wide belts is “cupping,” where the edges of the belt curl upward. Through our extensive expertise in welding techniques and manufacturing processes, we have developed innovative solutions, such as the integration of encapsulated filaments, to improve belt flatness.

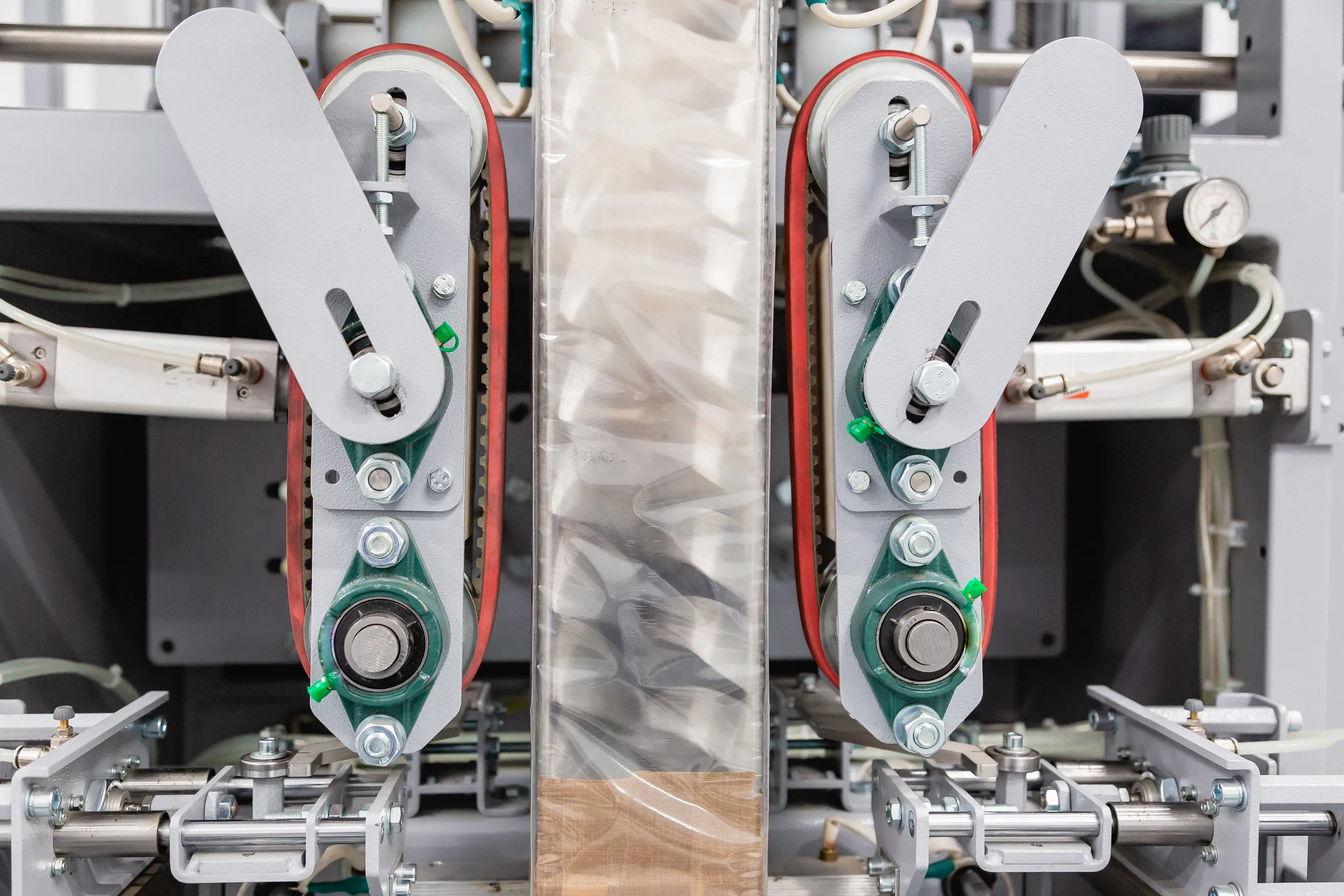

Precise guidance with the easy drive system

For optimum running stability of wide timing belts, we offer the patented easy drive system. This system prevents lateral displacement and provides highly controlled movement with improved positioning accuracy. It consists of a slot on the tooth side of the belt in combination with a patented easy drive ring, which we can accurately insert into the timing belt pulley.

Read more about our easy drive solutions

Vacuum conveyors for light and fast applications

Vacuum technology can provide a solution for transporting lightweight products at high speeds. By omitting Kevlar cords at the production stage, hole pattern application is facilitated and frayed Kevlar cords in the perforations are prevented. This contributes to efficient and powerful vacuum conveying.

Learn more about our vacuum belts.

Discover the possibilities for your Conveyor application

Questions about the possibilities with our wide belts?

Partners

Downloads

Related Products

Drive Technology

Conveyors

Vacuum belts

Special Timing Belt

Caldic Special Pulleys

easy drive Pulleys